Demand Forecasting in Supply Chain Technology

Table of Contents

- jaro education

- 6, March 2024

- 10:00 am

In this era of technological proliferation, global market dynamics are shifting at lightning speed. Therefore, the critical study of efficient supply chain management has become imminent. Demand forecasting is integral to supply chain technology – a systematic process that has become a strategic cornerstone in the contemporary business environment.

This blog delivers the different shades of demand forecasting. Further, it will disclose the transformative elements of demand forecasting techniques in developing an agile, robust, and budget-friendly supply chain for industrial domains irrespective of operational commitments. This blog offers executives at various management positions and entry-level professionals to discover new perspectives and equip themselves with the vital knowledge to drive the present organizations to attain their objectives.

What is Demand Forecasting?

The eventual role of demand forecasting in supply management is quite significant. It relates to optimizing operational capabilities and minimizing upcoming costs. Consequently, the procedures and practices implemented to attain the business goals are still being determined and predicated. The trending predictive AI-driven technological developments present the right circumstances to derive an appropriate demand forecasting strategy for proficient logistic tactics.

The discipline of demand forecasting involves a cyclical process. It uses historical data, the proven analysis of prevailing market activities, and complex templates to predict future demand directions. This foolproof prediction creates the basis for managing supply chains, controlling production inventory, planning shop floor commitments, and developing strategic decisions commensurate with ongoing business policies. The demand forecasting techniques thus create a perfect equilibrium between achieving client parameters and maintaining cost-effectiveness and so the whole process of supply chain technology leads to desired profit and business stability.

Importance of an Accurate Demand Forecasting?

Demand forecasting is crucial to the supply chain as it connects with a business entity’s core operational processes that involve (DDMRP) demand-driven material resource planning, manufacturing, financial planning, inbound logistics, and risk assessment. The following illustration will give a more elaborate reflection of the same.

A smartphone manufacturer has decided to launch the latest and much-awaited smartphone globally. The fierce market competition and limited production capacity force the company to forecast reasonable and accurate logistics to succeed in its venture.

The company professionals leverage current market trends, historical sales data, and precise consumer insights. They find that demand will rise during the shortly approaching holiday season. Valid forecasts help in-house managers strategically align their supply chain operations. It results in maintaining an adequate inventory level of raw materials, optimizing production schedules, and arranging high-end logistics for on-time product delivery.

As anticipated, the demand forecasting techniques are exact and accurate. There is sufficient replenishment of smartphone stocks in retail stores for target consumers that always stay within the inventory. With the help of its professional team, the company maximizes its return on investments with the bare minimum risk of under or overstocking.

Thus, the above illustration shows that demand forecasting enables the smartphone manufacturing company to allocate inputs skillfully, optimize the production capacity, and minimize surplus or shortage of inventory costs or missed sales opportunities. As a result, the company can remain afloat in the competition in the rapidly spreading electronics market for bulk consumers. With productive demand forecasting for logistics, businesses can anticipate uncertainties efficiently, use market opportunities, and ensure sustainable growth and profitability.

Types of Demand Forecasting in Supply Chain

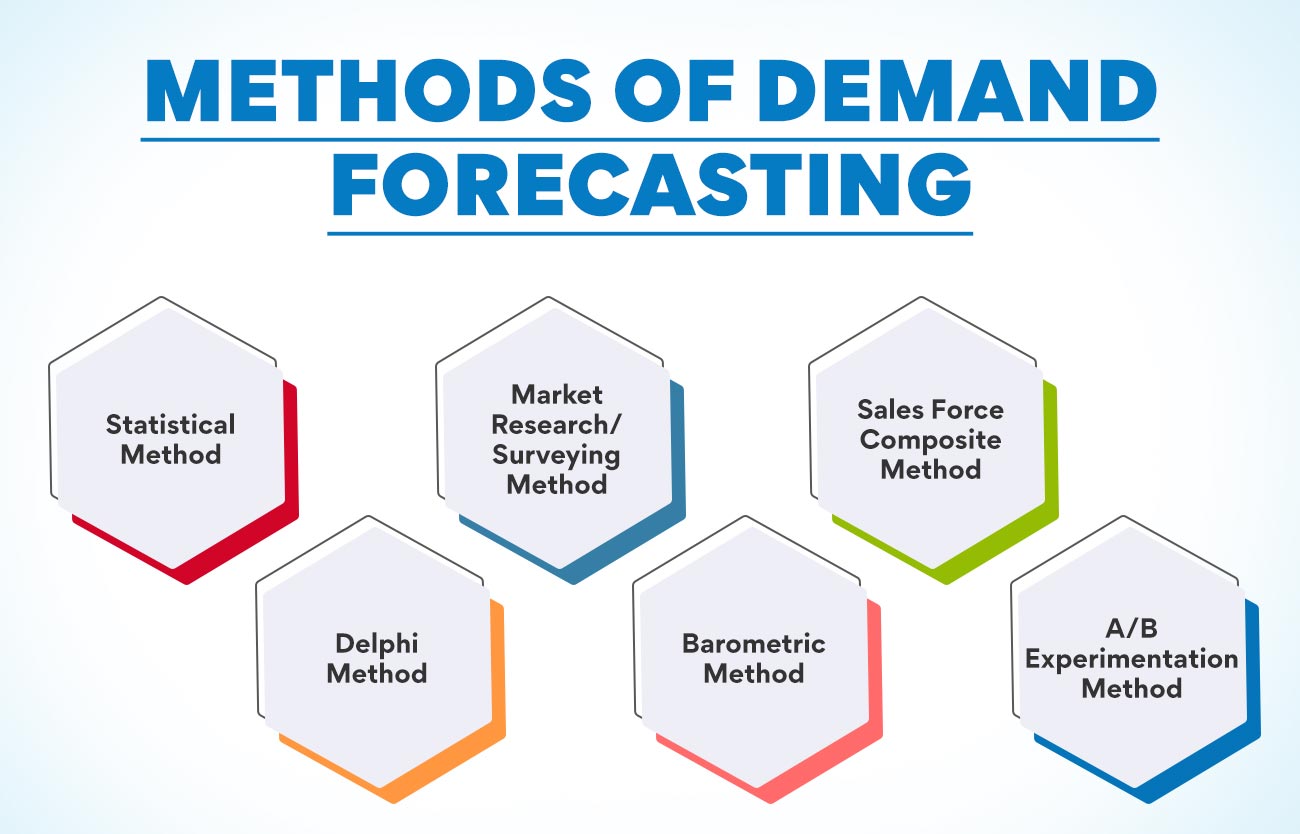

The demand forecasting methods solely depend on available data from the company owners. They collect the data through historical sales or proactive research. The available data directly correspond with the precision and effort put into demand forecasting in supply chain management. The various types of demand forecasting in the supply chain are as follows:

Time-Series Forecasting

It involves data-driven technology. The activities begin with researching past patterns to anticipate future consumer demands.

Qualitative Forecasting

When you need more historical data points or conceive a new market entry, qualitative forecasting is your ideal strategy. It includes expert opinion, intuition, and effective market research.

Casual Forecasting

It correlates cause and effect among probable variables. These variables may include the impact of economic indicators or marketing initiatives on demand. The predictive power is quite visible while driving critical business decisions.

Neural Networks (AI and ML)

These distinct techniques use the power of machine learning to find intricate and nonlinear relationships and are adaptable to new data sets. Their seamless handling of substantial data and detection of hidden patterns make them the superior method for demand forecasting.

Steps Involved in Demand Forecasting

Integrating demand forecasting technologies in business operations can revolutionize supply chain management. Therefore, the following steps are crucial to initiate this transformative journey:

Data Collection and Preparation

The primary step comprises gathering and preparing compatible and premium data. It may include past sales statistics, consumer preferences, market trends, and other relevant external factors. It is the groundwork of accurate demand forecasting

Model Selection

It will help if you recognize the most appropriate forecasting model that caters to your business demands. This model comprises various approaches like regression studies, time-series models, or ML algorithms. You must choose the best alternative that aligns with your data traits and forecasting requisites.

Integration with Supply Chain Management Framework

Integrate supply chain technology principles seamlessly into demand forecasting, fostering collaboration with stakeholders across divisions. This correlation extends to resource procurement, inventory management, and shop floor operations.

*edureka.co

Trending Demand Forecasting Software

In demand forecasting, you may discover a host of software that adopt superior supply chain technologies. A few of these platforms are as follows:

1. SAP Integrated Business Planning (IBP)

It can receive the requisite information from several sources. Consequently, it helps seamless collaboration across divisions and optimizes end-to-end supply chain operations. SAP IBP allows business enterprises to marshal their demand strategies with event-based financial objectives and make informed decisions as and when required.

2. Oracle Demantra

It signifies a robust and high-end demand management scenario. It provides advanced analytics and optimization devices concerning supply chain management and demand forecasting accuracy to ensure supply chain visibility. As a result, company management is in a better position to make data-driven decisions and calibrate their inventory levels for optimal performance.

3. JDA Demand Planning

It is highly trending software known for its comprehensive demand forecasting and inventory control skills. It uses complex algorithms that empower stakeholders to calibrate inventory levels, minimize stock shortages, and lower the cost of production. The user-friendly interface and top-notch analytical tools ensure the preparation of accurate demand plans and contribute to real-time decision-making.

4. IBM Planning Analytics

IBM Planning Analytics is an exceptional platform that provides powerful demand forecasting techniques and proficiency in scenario modeling. This platform also has analytics insight that helps businesses detect trends and patterns and make proactive decisions and so organizations can create precise demand strategies, align them with clearly defined financial goals, and optimize supply chain activities.

5. SAS Demand-Driven Planning and Optimization

The planning and optimization tool, SAS Demand-Driven Planning and Optimization, has become reliable for offering superior machine learning algorithms and sophisticated analytics. These competitive features allow large manufacturing companies to generate accurate demand forecasts and optimize supply chain activities. Besides that, this unique platform empowers businesses to recognize trends, optimize inventory levels, and increase operational capabilities.

These demand forecasting platforms allow businesses to conduct comprehensive research and development while balancing instant requirements with future targets. Off-the-shelf solutions are beneficial in many cases. Still, custom software is necessary to attain peak supply chain performance and gain a competitive edge in the complex market scenario.

Custom software facilitates exceptional flexibility, enabling corporate management to dictate the inherent tools to fuse with the in-house processes, requirements, and predefined objectives. These actions optimize every aspect of supply chain forecasting. Even though the initial investment might be substantial, the long-term gains surely outweigh the costs. The ultimate aim is to address industry-specific issues and challenges with the support of these contemporary platforms.

Best Practices in Demand Forecasting

Modern business enterprises must adhere to some of the best practices that are obligatory in demand forecasting:

Adoption of Superior Data

Precise and extensive data is essential for accurate demand forecasts. Regularly refreshing and ascertaining the historical data ensures their relevance and accuracy. Using state-of-the-art data analytics procedures is quite beneficial to disclose hidden patterns and insights.

Go for the Proper Forecasting Process

Choose the most authentic demand forecasting techniques corresponding to the nature and running of the business, product range, and demand patterns. These include trends, seasonality, and market fluctuations. You should keenly study these elements and select the most suitable method that optimally fits your needs.

Know the Demand Drivers

C-Suite level managers should acquire an in-depth knowledge of the drivers influencing industrial demands. The managers must consider critical market factors, customer behavioral patterns, and rivals’ activities in a similar domain. They should apply this crucial knowledge to demand forecasting models in a supply chain scenario to increase the accuracy and authenticity of predictions.

Collaborate across Company Divisions

The businesses must implement cross-divisional interaction among various wings, such as marketing, sales, purchases, finance, and operations. They should evolve the practices of open communication channels to collect insights, align strategies, and share knowledge. An efficient collaboration improves the authenticity of forecasts and cultivates proactive decision-making.

Corroborate and Update Forecasts Regularly

By reading through this far, you might have understood that demand patterns change with time. Therefore, it is always imperative to analyze and fine-tune the forecasts invariably. It confirms that your forecasts remain relevant and precise in the current market dynamics. It is also helpful to incorporate timely feedback from stakeholders and adjust the demand models accordingly.

Use Applicable Technology and Dependable Software

Company professionals at various corporate levels should utilize advanced supply chain technology and modern demand forecasting software to streamline the demand planning process. Software solutions that promote automation, real-time insights, and data visualization are always advisable as these reliable platforms improve forecasting accuracy, coherence, and scalability.

Combine Artificial Intelligence and Machine Learning Ingredients

The need of the hour is to merge the potency of AI and ML algorithms for demand forecasting in the supply chain. It helps uncover intricate patterns, identify anomalies, and precisely trigger forecasts.

Final Thoughts

Demand forecasting and procurement are the bases of a highly productive supply chain management system. This operational approach is the key to anticipating customer requirements and optimizing the buying process accordingly. Implementing demand forecasting techniques delivers immense potential for large-scale enterprises to effect cost savings, drive desired profitability, and enhance overall customer satisfaction.

Integrating qualitative and quantitative approaches, demand forecasting involves gathering insights from diverse supply chain-related data sources. Qualitative data, sourced externally from cultural trends, social media, news reports, market analysis, and competitor evaluations, is complemented by internally sourced information like customer feedback and preferences. These combined data points significantly contribute to painting a precise forecasting picture.

So, if you are a working professional at any management level, you must consider joining the Executive Certificate Programme in Supply Chain Analytics and Management offered by IIM Mumbai (NITIE), as this course will enable you to combat new-age supply chain challenges with the potential of AI/ML, through real-life case studies and projects. To know more, contact Jaro Education.

Frequently Asked Questions

Cybercriminals are continuously improving their attacking abilities with the help of AI. Now they are launching large-scale attacks by integrating AI technologies into their workflows. To prevent these attacks, you should utilise AI to analyse large volumes of data, reducing false positives from security alerts and cutting out bottlenecks from security alerts.

The major benefits of AI-based cybersecurity include –

- Quickly analysing large volumes of data

- Automating the repetitive cybersecurity tasks

- Predicting potential attacks and providing messages to the security teams

To become a professional in AI cybersecurity, you need knowledge about ML data modelling, language modelling, behaviour analysis, and deep neural networks. For cybersecurity, you need a clear understanding of network security, cryptography, malware detection, data protection, and computer forensics.

No, AI can perform specific tasks in cybersecurity, but it can’t completely replace human input.

Yes, the cybersecurity professionals can automate the mundane tasks with the help of AI.

Programme on Strategic Management

Programme on Strategic Management

Programme on Strategic Management

Programme on Strategic Management

Programme on Strategic Management

Programme on Strategic Management

Programme on Strategic Management