Implementing 5s in the workplace: How to use 5s in the lean production

Table of Contents

- jaro education

- 25, March 2024

- 2:00 pm

Introduction

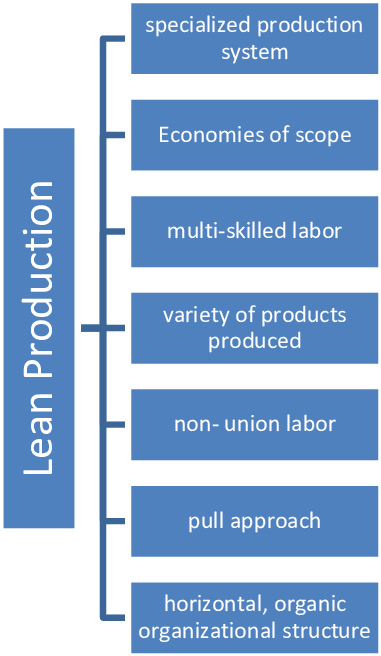

Adopting activities that help maintain orderliness in the work environment is vital for the smooth operations of a company. And, this can be achieved by introducing 5S in the workplace. This approach not only helps employees learn to reduce waste, in-process inventory and unplanned downtime but also improves their working conditions.

Besides learning to clean up and optimise productivity, lean 5S methodology helps achieve more consistent operational results. This method focuses on organising the workplace in its existing configuration. Further, these efforts lead to developing and sustaining a productive work environment.

A typical 5S implementation plan can help reduce the requirement of physical space for existing operations significantly. And, this can be achieved by organising tools and materials into labelled and colour-coded storage units.

Notably, the 5S method for lean production lays the ground for other similar strategies like TPM, cellular manufacturing, just-in-time production, and Six Sigma to thrive.

*blog.proactioninternational.com

Lean 5S Methodology

5S is a system that helps develop a workplace that is clean, safe, uncluttered and well-organised, leading to waste reduction and productivity optimisation. Applied to a workspace that is suited for visual control and lean production, the 5S methodology aims at creating a quality work environment that is critical to employees physically and mentally.

Developed by Hiroyuki Hirano in post-war Japan, the 5S and lean methodology was first adopted by Toyota. Notably, Toyota gained international recognition as a quality automobile manufacturer after integrating 5S principles into its production framework. Considering this success story, businesses across different industries started to take the 5S approach. And, companies like Boeing, Caterpillar, Harley-Davidson, HP, Nike, and Ford, benefited from the adoption of lean 5S methodology.

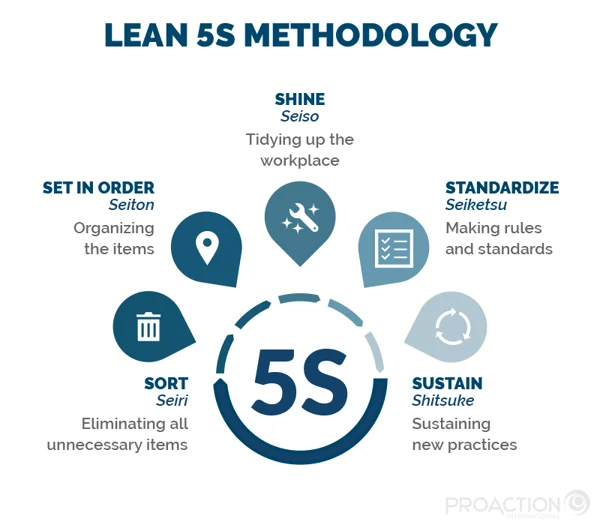

Derived from Japanese terms beginning with the letter “S”, 5S pillars are vital to implement to elevate the work environment. And, they include the following:

- Seiri is translated to organise (or sort) in English. This step demands separating needed materials from the unneeded stuff and later removing the latter.

- Seiton is translated to orderliness (or set in order) in English. This calls for neatly arranging and identifying different materials for ease of use.

- Seiso is translated to cleanliness (or shine) in English. This simply asks to conduct a clean-up exercise.

- Seiketsu is translated to standardise in English. It requires following the earlier-mentioned three steps, including organise, set in order and shine, to maintain a workplace in its perfect condition.

- Shitsuke is translated to discipline (or sustain) in English. This S emphasises developing the habit of following the first four Ss.

By and large, the lean 5S methodology is well explained by the popular idiom: “a place for everything and everything in its place.”

Let us now understand 5S in the workplace with the help of an example.

A public health insurance programme team utilised the 5S tool to improve the enrollment template. First, they sorted the fields and the unnecessary ones were removed. Then, the remaining fields were arranged in an order. Next up, the team created a database that would reject duplicate entries. Lastly, the spreadsheet was standardised to create a template. With the help of Microsoft Access and Microsoft Excel, the team was successful in creating a self-sustaining system.

Indisputably, the lean 5S methodology is a low-investment, high-impact tool that engages employees in owning their workspace and helps cultivate a culture that thrives on productivity, improvement and quality.

Purpose of 5S in Workplace

The following 5S activities lead to not just creating but also sustaining efficient and effective work areas:

- Eliminating what is not required

- Organising what is left after sorting

- Declutter the work area

- Writing standards for 5S

- Consistently applying the 5S standards

Besides, it is important to pay attention to another S that stands for safety in the workplace. While the lean 5S methodology acts to develop a great place to work for everyone, it is equally important to prevent workplace injuries. In order to keep employees motivated and productivity high, 5S in the workplace must be laid out logically to ensure that everyone enjoys a safe and clean work environment.

5S and Lean Methodology Benefits

*researchgate.net

Here are the advantages implementation of lean 5S programs brings along:

- More space availability

- Higher equipment availability

- Better asset utilisation

- Reduced costs

- Improved safety

- Increased production agility and flexibility

- Lower defect rates

- Improved employee morale

- Enhanced enterprise image to customers, suppliers, employees, and management

Implementing the 5S Method

Following are the steps to implement the lean 5S methodology:

1. Sort

The step helps you segregate and organise things between what is used and what is not. And, this tells you to park the latter category items in the holding area. Removing unneeded clutter allows having a more productive workspace. Not just this, eliminating distractions saves space for other things in use.

While separating necessary items from the unnecessary lot, take the categorisation approach. First, prepare a set of items that are needed in the main work area. These items include the materials that regularly come in use and must stay in the main work area. Second, group items that are needed in another work area, such as misplaced items. Hand over such items to the member responsible for that work area.

Next up are the items that fall in the category of may be needed. For things with unsure thoughts, tag them as no longer needed. And, assign them for review to the member who will take the call of disposal. Last but not the least comes the items that are not needed at all. Such things must be discarded immediately, recycled, or donated/sold if they are in good condition.

Here are some classic examples of the sort exercise:

- Segregating everyday tools and special-case items

- Designating an overflow area for duplicate materials

- Waste removal from workspace

- Discarding broken or old parts

- Avoid stuffing the workspace with excess materials

- Recycling materials and paper

Sorting activities not only declutter an area to create more space, but also helps prevent injuries. For instance, better space for movement in aisles can help avert tripping hazards.

2. Straighten/Set in Order

This step of the lean 5S methodology necessitates to organise the items that are left after sorting. This makes the frequently used items easily accessible by assigning a designated place to them.

The straighten step ensures that every item gets a specific home so that they can be easily found and returned to the place they belong. As things get placed in more ergonomic locations, the step reduces the waste from excess motion. Also, this creates space that can be strategically used to improve production.

Besides, the following strategy can be adopted to organise the sorted items:

Give preference to frequently used items and provide them easy access. This will also help reduce waste from excess motion. Then, take up the task of grouping the like items into logical categories. In addition, visual designs can be utilised to highlight when an item goes missing. Going for a shadow board for tools is amongst the best examples that qualify the category of visual designs.

Apart from the aforementioned ideas, containers can be used to organise things. And, the items that do not fit into a container can be given a frame along with a label.

The straightening activities will bring a significant improvement to the workplace. This exercise can be taken up as a team task in order to address any limitations or suggest further improvements to the existing plan.

Here are some activities that qualify as a typical straightening task:

- Giving every item a distinct home

- Assigning a separate area for shadow boxes and tool storage

- Using colour codes while organising

- Making use of shadow boards and other visual indicators

As straighten activities focus on providing everything an employee needs within his/her easy reach, this saves them from rushing around hunting for items they require regularly. Additionally, organising things helps avoid chaos that can cause any safety hazard.

3. Shine

A part of the lean 5S methodology, the shine step elevates the work area. Shine activities ensure that all the required tools, equipment, and other items are thoroughly cleaned. This also involves scheduling routine maintenance of equipment involved in the production.

Creating a work environment that engages and empowers employees, this step lets them enjoy more responsibility and agency over their work area. This also offers opportunities to identify problems way before they interrupt production. For instance, issues like fluid leaks, metal shavings from unexpected wear or material spills, can be easily noticed in a clean work environment.

To elevate the work area, employees can grab a spray bottle filled with appropriate cleaners and make the workstation sparkle. While performing this task, remember the guiding principle of ‘clean to understand’. This means taking a moment to examine the item, tool or machinery involved after cleaning. Check if it needs any repair or maintenance. If you observe any unexpected debris, then try to find its origin and save everyone from a future problem.

Let’s have a look at some shine activities that must be performed to elevate the workspace:

- Looking for any signs of wear on tools

- Wiping down equipment

- Investigating recurring mess

- Disassembling larger objects to inspect them

- Following proper procedures laid down for cleaning equipment

Cleaning the workspace and maintaining equipment ensure a safe work environment for each and every employee. Shine activities help avert hazardous events.

4. Standardise

When talking about 5S in the workspace, the standardise step acts as a bridge between the first three 5S steps, namely sort, straighten and shine, and the last one, sustain. This step makes a note of the best practices to standardise work. Notably, creating a set of standards leads to inculcating clean habits.

Standardising work ensures that the implementation of lean 5S methodology translates into a reproducible set of activities. This also establishes that the 5S tool is not a one-time project. But, all the efforts that have gone into implementing the lean method continue to pay dividends in the future. This step lets you set expectations for the future with a standardised, documented process to follow in the workplace.

To achieve the set goals through the standardise step, it is important to work in pairs. This ensures that nothing vital is missed in the document laid down for standardising work practices. Also, it is important to be mindful about capturing every task. Including short checklists that are organised by role, shift and frequency can make it easier for everyone to access what is important. Always give a name to every task and explain in detail for training purposes.

Below mentioned are the typical examples of standardise activities:

- Writing down standard practices

- Creating checklists for day-to-day tasks and audit purposes

- Building a schedule for tasks

- Developing special kits for performing specific tasks

This step lays clear instructions about what and how a task must be performed. Developing a standard document that comprehensively talks about every task involved in the production helps keep any confusion at bay.

5. Sustain

Ensuring that the lean 5S methodology is continuously applied, the sustain step helps transform the standardised processes into regularly completed tasks. It is important to consider that the changes suggested through the 5S method to improve the workplace can be easily adapted to create a safer work environment for everyone involved.

In order to ensure further and continued progress, it is vital to follow standardised practices on an ongoing basis. After creating scheduled tasks, training employees is of utmost importance. Teaching through demonstration will help them gain confidence and perform the task as expected on their own. During this process, it is important to supervise them and offer corrections when needed.

Also, be open to making changes that can make the task not just efficient but easier too. It is important to receive feedback on standard practices laid down to perform different tasks to improve processes.

The following are some examples of sustainable activities that are taken up to implement 5S in the workplace:

- Demonstrating complex and/or multi-step processes

- Teaching employees to conduct audits

- Conducting periodic checks post-initial training

- Accommodating constructive feedback to improve 5S implementation

- Responding to mistakes with additional training

Sustain activities make sure that employees not just stay happy but safe too while working. There can be nothing more dangerous than an unmotivated employee who does not care about maintaining his/her workplace. It is important to acknowledge employees’ participation in the 5S and lean programme and appreciate the same in order to keep them motivated.

6. 5S Tools for Visual Management

For the successful implementation of lean 5S methodology, visual management is key. Related to the concept of ‘the real place’, visual management helps make the situation clear by looking at it or being a little observant. Notably, it is easy to fix what is visible but there’s no solution available to what can’t be seen.

Visual management includes visual displays or visual controls that help prevent any abnormality from occurring. Also, data displays can be used to supervise a quality or process problem. This often involves other video or audio signals highlighting a defect or another issue. Further, dashboards can help gauge abnormalities in the production processes.

Besides, floor markings laid using reflector tape can be utilised to mark work areas or hazardous regions. Similarly, labels can reflect the contents of containers, highlighting potential hazards. They can also denote specific locations for finished goods, raw materials, and shipping. Wall signs and banners can be used too to show the way to storage and clean-up areas.

Tool organisation cannot be skipped when talking about visual management. Shadow boards, featuring the outline of each tool, can be used. Or, different sizes of wrenches can be organised using kaizen foam. This also helps identify when a tool is missing.

Another vital thing to pay attention to is layout. Machines must be arranged in an order that reflects the product flow. This makes it easy to visualise the process involved and identify bottlenecks. But, it is different in job shops where machines are arranged in functional groups.

Conclusion

Quality and productivity are amongst the most critical and crucial areas of concern. Whether it is a small business or a big one, safety and standardisation are vital to enhance production. To boost operational effectiveness, lean techniques like 5S in the workplace must be employed. The lean 5S methodology not just helps enhance performance, but also continuously better the products and processes involved.

According to ResearchGate, the 5S system contributes over 50 per cent of the industrial production. And, all this can be attributed to the efforts of decreasing waste and optimising quality and productivity by monitoring the work environment.

To understand effective tools like 5S and drive business growth, it is important to enroll in industry-relevant courses like Post Graduate Certificate Programme in Product & Brand Management by IIM Nagpur. This 10-month course is carefully tailored for candidates willing to cultivate strategic acumen. Focused on product strategy, the programme is meant for mid to senior-level professionals who are engaged in product development and management roles. To know more, contact Jaro Education.

Frequently Asked Questions

The lean 5S methodology can lead many businesses on the way to success when implemented right. Adopting 5S tools teaches employees efficient ways of getting their job done. And, this makes it vital to improve any workplace. Businesses can maximise the benefits of implementing 5S in workplace by proactively cutting down the waste of any nature, organising things and standardising processes.

Irrespective of the industry, the 5S method can be applied to any type of operation. Adopting 5S lean practices can help if operational efficiency is dissatisfactory, manufacturing costs are increasing, customer complaints are rising and there is a lack of consistency in quality and output.

Reduction in waste of any nature, including overproduction, inefficient movements, unnecessary steps in transportation, defects in products, overprocessing and idle time, can be achieved by implementing the lean 5S methodology. In addition, it helps achieve improved productivity and safety at the workplace.

Executives hailing from the retail, product, IT, and consulting domains can benefit from the course.

Yes, candidates successfully completing the programme will get alumni status.