What is the Difference Between Logistics and Supply Chain Management?

Table of Contents

- jaro education

- 9, July 2024

- 9:00 am

Logistics and supply chain management are essential components of corporate operations that guarantee the smooth flow of information, products and services from the place of origin to the final customer. The precise coordination of several intricate processes, such as shipping, inventory control, storage and packing, is known as logistics. The primary objective of logistics is to ensure the timely and economical delivery of items.

Contrarily, supply chain management covers a wider variety of tasks including distribution networks, production procedures and the sourcing of raw materials in addition to logistics. In a globalized economy satisfying customer expectations, preserving competitive advantage and responding to market shifts all depend on efficient supply chain management

Scope of Logistic

The vast scope of logistics includes order processing, inventory control, transportation, warehousing, material handling, and packaging. The entire functions of logistics management are integrated throughout a network of facilities. Supporting operational needs for production, customer service, and procurement is the ultimate objective of logistics management. To connect internal and external operations as a single integrated process, it aims to internally coordinate functional competency into an integrated operation focused on serving customers and externally ensure operational synchronization, which is crucial for customers as well as material and service suppliers.

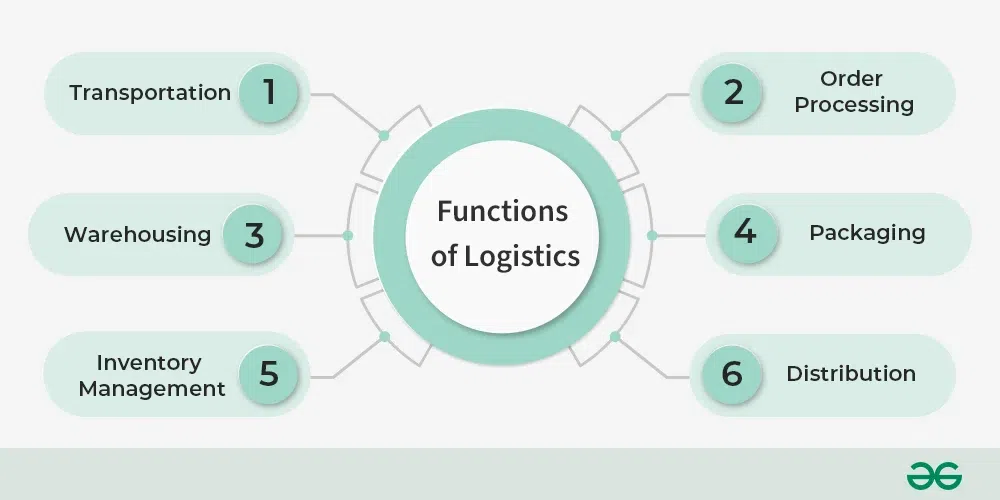

Functions of Logistics

Six primary functions are related to efficient logistic management. These functions ensure that the company maintains a smooth flow of operations related to the timely delivery of products.

geeksforgeeks.org*

Proper transportation and timely delivery

This is one of the pivotal functions of logistics, as it entails choosing routes, deciding on forms of transportation and controlling transportation expenses. Proper management of the transportation routes does not involve delivering products from one point to another; it also needs to be done quickly, effectively, and affordably. It also helps in managing a complicated transportation network that involves regulatory compliance and shipping cost optimization.

Proper processing of the order

It is one of the most essential functions of logistics, including obtaining, processing, and confirming customer orders. As the initial stage in the actual delivery of products, it is a crucial component that links to maintaining proper inventory management with customer requirements. A customer’s experience may be greatly enhanced by efficient order processing as it increases satisfaction and loyalty.

Packaging

One of the fundamental functions of logistics is safeguarding goods throughout the route and making sure they get to final consumers undamaged. Since it has an impact on how things are handled, preserved, and stacked, appropriate packaging is also crucial for material storage and transportation processes.

Proper handling of the products

This feature ensures that goods are moved between sites or inside a warehouse securely without sacrificing the quality of the final product. It also includes the deliberate use of economic tools and techniques that will improve worker productivity.

Maintaining proper records of the warehouse

Maintaining records regarding the stock stored in the warehouse involves the proper arrangement of the items that maximizes both space and accessibility. Logistics plays a crucial role in order fulfillment and ensuring complete customer satisfaction by guaranteeing that items are easily accessible for packaging and delivery.

Managing the inventory

Significance of Logistics

Effective logistics and supply chain management results in satisfied customers and suppliers. In addition to creating satisfied consumers, logistics management has several benefits.

- With the help of effective logistics management, businesses benefit from increased client interactions, operational visibility, and a reduced requirement for maintaining surplus inventory. As a result, the order fulfillment rate, along with better client relations, raises the business’s profitability.

- Effective logistic management may help make operations more transparent and visible. After carefully analyzing the logistics management plans and historical data, logistics managers might be able to arrange proper route optimization, which can enhance productivity.

- Logistics is also known for supporting a well-synchronized supply chain management of the products.

- Better logistic management techniques enhance product transportation and eradicate disturbances like delayed deliveries. Therefore, delivery services will be upgraded to a higher quality, ultimately resulting in an improved client experience.

Scope of Supply Chain Management

The scope of supply chain management is huge and involves a wide range of applications. As it involves several distinct areas, including production, warehousing, packaging, transportation and delivery, information technology, and logistics, the supply chain generates a large number of jobs in a variety of industries.

Functions of Supply Chain Management

Supply chain management comprises five functions crucial for maintaining an effective transportation of goods and services.

businessprocessincubator.com*

Logistics

Logistics is the planning and execution of every element of supply chain operations, including transportation, inventory control, and warehousing. Effective communication is essential for businesses to maintain with all supply chain managers to guarantee that goods are delivered to customers in the exact shape and at the right time.

Flow of information

One crucial function is ensuring that information is properly transferred between supply chain participants. If the information is not communicated well or the flow is moving poorly, the entire process may suffer from obstacles, delays, and errors.

Obtaining products

It is the procedure for purchasing the supplies required to make goods. Suppliers that sell these products should be able to provide them within the manufacturer’s deadline. To guarantee prompt material delivery, the manufacturer’s businesses and suppliers must cooperate and communicate.

Proper management of the resources

The planning, organizing, and control of resources is known as resource management. The labor force, raw materials, and technology needed to transform things from their raw state into consumable final goods are referred to as resources. To maximize system performance, effective management of supply chains incorporates allocating all of these assets to the appropriate supply chain tasks.

Operations

Everything a business does to operate its operations daily is referred to as operations. A business must be able to project the need for its products before making the necessary material purchases and initiating production. Forecasting is estimating, as it predicts the volumes of a product that will be sold in a specific time frame. Accurate forecasting must be in line with stock administration and manufacturing plans to guarantee that the business is operationally positioned to produce the appropriate quantity of product to satisfy customer demands.

Importance of Supply Chain Management

Supply chain management is known for reducing additional costs that are associated with the transportation of products. Other than that, let’s take a look at the additional benefits of supply chain management.

- Businesses can identify production delays because real-time data is easily accessible. This allows businesses to put in motion backup plans in advance, such as locating a different supplier. This saves time for everyone involved in the process and increases the overall effectiveness of product delivery.

- Another advantage of the easy accessibility of real-time data is that it helps supply chain management teams anticipate demand accurately, reducing overhead costs. By optimizing warehouse layouts and using suitable automation technologies, the business may enhance productivity and establish a more effective inventory management system.

- Supply chain management covers every facet of the business’s service, from creation to fulfillment. Because of the supply chain integrated software, managers now have improved data access. This facilitates data exchange, which improves access to the whole supply chain.

- Supply chain management involves reducing costs related to product shipment. Hence, the most critical part of a supply chain manager is to identify efficient and effective methods of product shipment.

- One of the most significant importance of supply chain management is that the managers have the authority to establish a uniform minimum quality standard related to the protocols of delivering goods and services. This also creates pressure on the suppliers to follow the standard procedures related to maintaining the quality of delivering products that are developed by the company.

Differences between Logistics and Supply Chain Management

Logistics and supply chain management have numerous similarities, but certain key differences set a boundary between them. Let’s now understand the key differences between logistics and supply chain management.

| Basis | LOGISTICS | SUPPLY CHAIN MANAGEMENT |

|---|---|---|

| Meaning | Logistics emphasizes the effective movement and storage of products and services from the starting point of origin to the end point of consumption. | Supply chain management oversees the complete supply chain, from obtaining raw materials to delivering the finished product. |

| Measurement of performance | Logistics assesses performance regarding warehouse productivity, delivery punctuality, and minimized transportation expenses. | Supply chain management evaluates its performance in terms of reduced cost, efficient supply chain management, and complete customer satisfaction. |

| Key components | The key logistics components include fulfillment of customer orders, inventory management, transportation and warehousing. | The key components of supply chain management include sales, customer satisfaction, the distribution of goods and services, and product procurement. |

| Implementation of technology | Logistics primarily uses technology to monitor and control the movement and storage of commodities. | Supply chain management incorporates cutting-edge technology for thorough supply chain management and optimization. |

| Scope | Logistics is primarily focused on moving stored products from one place to another. | Supply chain management covers important elements, including sales, marketing, distribution and customer satisfaction. |

| Focused areas | Logistics accelerates the supply chain's treatment of the transportation, storage, and associated information of products. | Supply chain management involves working with every supplier in the supply chain to maximize resources and improve customer satisfaction while maintaining perfect coordination among supply chain management partners. |

| Purpose | The primary objective of logistics is maintaining safety along with effective distribution and storage of commodities to satisfy client demands. | Supply chain management aims to produce products on schedule and under budget by optimizing the whole supply chain. |

| Type of decisions | Logistics focuses on operational choices about distribution, storage, and transportation. | Supply chain management involves making tactical choices about inventory control, distribution, and manufacturing. |

Conclusion

Logistics and supply chain management are important in ensuring that products and services are produced, consumed and moved efficiently. Through efficient resource management, process optimization, and technological utilization, organizations may boost their competitiveness, curtail expenses and elevate consumer contentment. Strong logistics and supply chain management plans are becoming more and more crucial as worldwide markets continue to change by stimulating innovation and industry collaboration.

The concept of logistics and supply chain management involves an in-depth understanding of the transportation routes and delivery of the products. Bachelor of Business Administration (BBA) provided by Chandigarh University provides accurate insights into the world of logistics and supply chain management. This industry-oriented program offers dual specializations to the enrolled students, and professionals teach all the topics in the syllabus with years of industry experience. Moreover, these professionals will impart applicable knowledge in the real world. Do not miss out on this opportunity to learn about this concept from Chandigarh University and get job portal access to over 300 hiring partners.

2 thoughts on “What is the Difference Between Logistics and Supply Chain Management?”

Thank you for sharing your insights with us. We appreciate your thoughtful comment.

Thanks for the detailed insights! Your input enriches the topic and provides a broader understanding.