Factors Influencing Supply Chain Design Decisions

Table of Contents

- jaro Education

- 19, July 2023

- 4:56 am

Whether you are a student exploring the field of operations or a professional already working in logistics, understanding the fundamentals of supply chain design is essential in today’s global business environment. Every product you buy—be it groceries or gadgets—goes through a meticulously planned network. But have you ever sat back and thought about all that goes into designing that network?

Supply chain design decisions are much more than just moving the goods from point A to point B. And from picking the right supplier, finding the best place to build warehouses, cost management, meeting delivery times, and consumer needs to bearing in mind all the environmental considerations, these factors determine how well a company performs, how efficient it becomes, and how happy its customers really are.

In this blog, we shall look into the major coordinating inputs and Network design in the supply chains, thus providing you with an understanding of how businesses create systems that are intelligent, flexible-coordinated, and cost-effective to remain competitive. Whether you’re a beginner or have some experience under your belt, this guide will fine-tune your understanding of how supply chains work in reality. Read further to know more about the factors influencing supply chain management.

What is a Supply Chain Network Design?

Before coming to the supply chain network design, it is important to understand what a supply chain is and why it is important for any firm. To put it in simple words, a supply chain is a process that starts with making a product and ends with selling it to clients. The Network design in the supply chain encompasses all processes, from obtaining raw materials to delivering completed items. Information is another critical component of supply networks. Aside from items moving from one end to the other, information must also move quickly in both directions.

Supply chain network design is the blueprint for how goods, information, and finances flow from suppliers to customers. It ensures that resources are allocated efficiently, customer demands are met promptly, and operational costs are minimized.

Supply Chain Design and Models

The process of making crucial decisions regarding the various aspects of the supply chain is known as supply chain design. A well-designed process will ensure smooth operation and benefit the firm. A Network design in the supply chain consists of different parts, each of which must be at the proper location for the organisation to profit from them. A good design aims to improve the flow of commodities and ensure optimum efficiency. Several elements will impact the design’s creation.

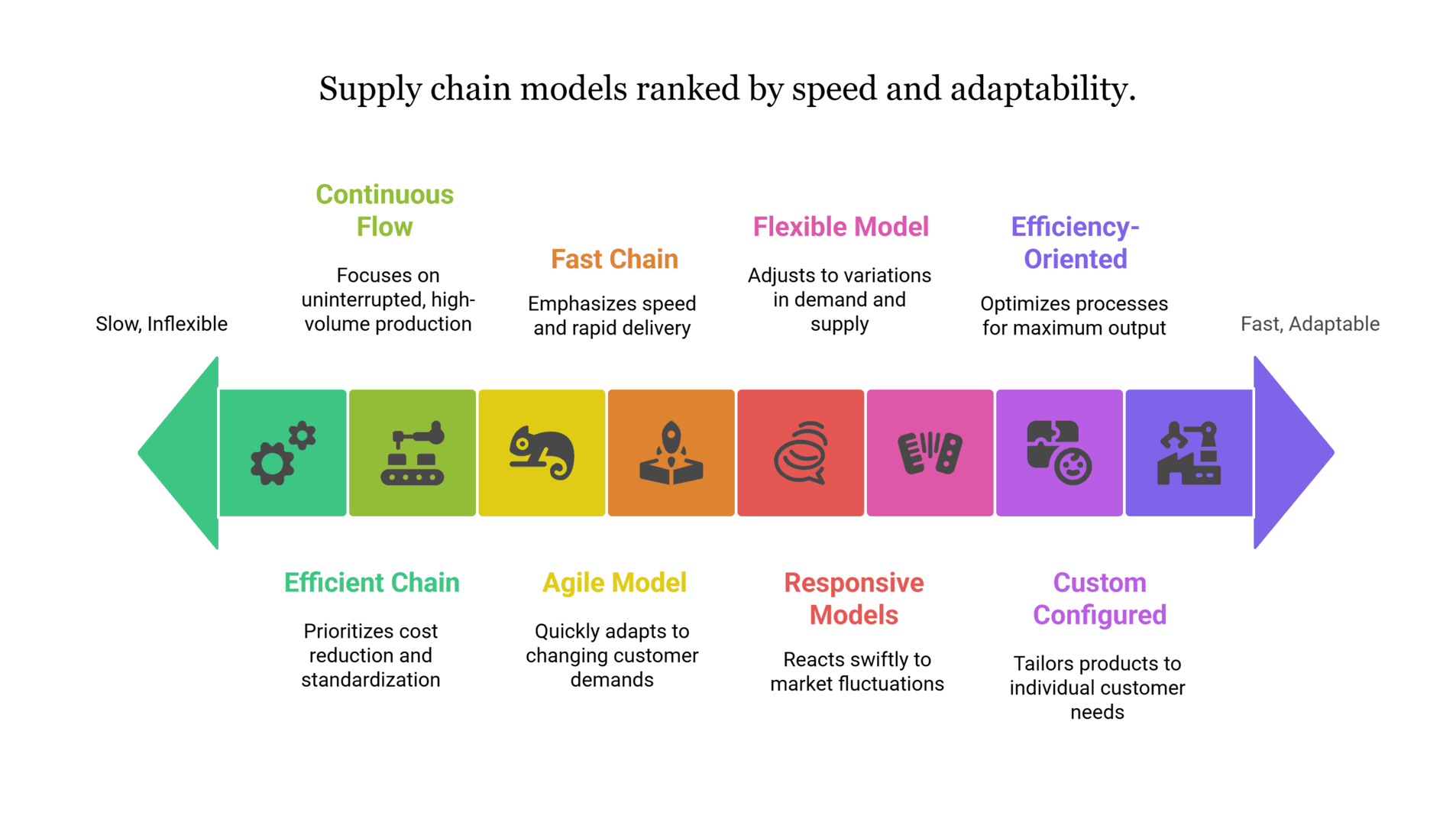

For different requirements, the experts have designed 8 supply chain models. These are:

- The Agile Model

- The Continuous Flow Model

- The Flexible Model

- The Fast Chain Model

- Responsive Models

- Efficient Chain Model

- The Custom Configured Model

- Efficiency-Oriented Models

These models offer several advantages since they can adjust their stocks and production patterns to match changing client needs. However, these models also come with various disadvantages. They rely significantly on their staff’s forecasting abilities to foresee trends. If personnel are not thoroughly trained for the task, they may make costly mistakes that may go against the organisation. These models need a significant amount of human interaction. This can result in instances of human mistakes.

Factors Influencing Supply Chain Design Decisions

Supply chain design is an important part of all businesses, which involves the movement of goods, services, or information. As a global company or a start-up, your approach with regard to your supply chain design determines your cost effectiveness, customer satisfaction, and overall business performance. So, what does it take to come up with such design options? For factors influencing Distribution Network Design.

So, what are some of the main factors influencing Distribution Network Design that affect the design of a supply chain? Let us elaborate.

1. Customer Requirements

Customer expectations are one of the greatest fuels of supply chain design.

- Do your customers anticipate next-day delivery?

- Do they desire customized products?

- Are they spread around the world, or are they localized within an area?

Your Network design in the supply chain should be designed according to the required level of speed, flexibility, and the requirement for accuracy by your customers. Such a responsive supply chain might be costly, but it is required by rival business sectors such as online retailing or fashion.

2. Cost Considerations

The factor of cost is very important in the Network design in the supply chain decision. All activities are associated with a price tag: from obtaining raw materials to delivering the end product.

The important cost drivers are:

- The cost of Transport and logistics

- Inventory carrying cost

- Warehousing expenses

- Labour and operational overhead

- Investment in either capital technology or infrastructure

This will be to strike a balance between cost and service. A cheap Network design in the supply chain means to save some money, but it can cause delays and disappoint customers without the right management of it.

3. Product Characteristics

The product that you are dealing with is going to affect the factors influencing Distribution Network Design of your supply chain a great deal.

Such questions are:

Does the product go bad, or is it non-perishable?

Does it take up a lot of space or not?

Will it be a high-ticket product?

As an example, perishable objects such as food or medicine need the maintenance of the cold chain, whereas large items, such as furniture, must be stored and transported in a certain way.

4. Location Decisions

The decision on where to erect your manufacturing plants, warehouses, and distribution centers is a strategic one.

The important ones are:

- Proximity to customers and suppliers

- Availability of transportation lines

- Supply of a quality workforce

- Tax and regulatory policy at the local level

A good site might cut down the time to transport goods and operational expenses and enhance the level of service.

5. Supplier Capabilities and Relationships

Suppliers are the backbone of any supply chain. Their reliability, speed, and flexibility can either support or disrupt your entire operation.

Factors to consider:

- Lead times

- Production capacity

- Geographical location

- Willingness to collaborate

Building strong, long-term relationships with suppliers often leads to better communication, faster response times, and improved quality control.

6. Technology Integration

In today’s digital world, the right technology can make or break your supply chain.

- ERP systems and supply chain management software

- Real-time tracking through IoT

- Artificial Intelligence for demand forecasting

- Robotics and automation for warehouse operations

Technology enables visibility, efficiency, and agility, helping you make better, data-driven decisions.

7. Market and Demand Dynamics

Demand isn’t static—it changes with trends, seasons, and customer preferences. Your supply chain should be designed to adapt to these changes.

Consider:

Seasonal demand spikes

Regional preferences

Global vs. local market needs

A flexible supply chain that can scale up or down is essential for managing uncertainty and customer expectations.

8. Regulatory and Legal Environment

Every region or country has its own set of rules. Ignoring them can lead to penalties, delays, or bans.

Regulatory factors include:

- Import/export laws

- Environmental standards

- Trade tariffs and duties

- Labor and safety laws

Designing a supply chain that complies with international and local regulations is a non-negotiable requirement.

9. Risk Management

Risk is an unavoidable part of supply chain operations, whether it’s political unrest, natural disasters, or pandemics.

Your supply chain design should include:

- Risk assessment models

- Contingency planning

- Supplier diversification

- Inventory buffers

Companies that invest in resilient supply chain structures recover faster and serve their customers better during disruptions.

10. Sustainability Goals

Sustainability isn’t just a buzzword—it’s a business necessity. More companies are now designing their supply chains to be environmentally and socially responsible.

Sustainable design includes:

- Reducing carbon emissions

- Using recyclable materials

- Minimizing waste

- Ethical sourcing practices

Not only is this good for the planet, but it also enhances brand image and customer loyalty.

How Jaro Education Helps You Choose the Right Career Path

Jaro Education is a recognized brand in career counseling, with thousands of clientele of students and working professionals getting clarity about the future. Having a success rate of more than 85 per cent of the learners attaining their desired career outcomes, Jaro Education integrates the expert counseling processes, the personalized learning plans, and the industry-aligned programs that can help the learners to make the right choice regarding their goals and abilities. The platform collaborates with the most highly ranked universities and creates flexible, accredited programs across such disciplines as management, technology, and data science, making career switching and upskilling affordable and efficient. Being a fresh graduate, you do not know what direction you should proceed in, or you are a working professional but wish to grow in your profession. Jaro Education is a good constant guide at any point in your career life.

Final Thoughts

Supply chain design is a great way to optimize and manage an organisation’s supply chain. The modelling technique allows for the examination of various situations and assists in determining the optimum supply chain decisions. While this process is very expensive, the benefits vastly exceed the costs.

If you want to expand your horizon on supply chain designs and logistics, then the Post Graduate Certificate Programme in Supply Chain Operations & Analytics (SCOA) is a suitable course to be a part of. In this 12-month course, participants can gather the necessary skills and expertise to boost their supply chain and data strategy. From this course, candidates can also indulge in interactive chamber consulting and work on capstone projects.

Frequently Asked Questions

A: Supply chain network design is the process of structuring a company’s supply chain to determine the optimal locations for factories, warehouses, distribution centers, and suppliers. It aims to minimize costs while maximizing service levels and efficiency.

A: It ensures that goods and services move efficiently from suppliers to customers, reducing costs, improving customer satisfaction, and enabling businesses to respond quickly to changes in demand or disruptions.

A: Major components include:

- Suppliers and vendors

- Manufacturing plants

- Warehouses and storage facilities

- Distribution centers

- Transportation routes

- End customers or retail outlets

A: Important factors include:

- Customer demand and service expectations

- Cost of transportation and warehousing

- Location of suppliers and markets

- Regulatory and trade considerations

- Product characteristics (e.g., perishability)

- Technology and data availability

A: The goal is to design a network that delivers products to customers at the lowest possible cost while maintaining high service levels, flexibility, and risk resilience.