What Is Lean Management? Definition and Core Principles

Cut the clutter. Boost the value. Work smarter, not harder. That’s the heartbeat of Lean Management. Waste is the common enemy of any company that continues to compete and innovate in the race against time, cost, and competition. It’s not only physical garbage, it can refer to lost time, energy or opportunities.

Lean Management should not be viewed as "just" a trend; rather, it is an effective way of thinking so businesses can create more value with fewer resources while preventing employee burnout. Lean thinking helps businesses achieve their desired performance ahead of their top competitors. This concept has proven effective for both startups and large companies by improving process efficiency and delivering better outcomes for customers.

If you have ever wondered how the most successful businesses deliver their services with the least amount of resources, Lean Management is the secret behind it.

Table Of Content

Lean management Definition

Key Objectives of Lean Management

5 Core Principles of Lean Management

Types of Waste in Lean Management: DOWNTIME

Lean Tools and Techniques

Benefits of Lean Management

Real-World Examples of Lean Management

Want to Be Proficient in Lean Management?

Conclusion

Frequently Asked Questions

Lean management Definition

Lean Management is a way of running a business by removing unnecessary steps from processes and focusing only on what truly adds value for the customer.

In simpler words, it helps businesses cut waste, save time, reduce costs, and deliver better results using fewer resources.

Companies use lean management because it:

- Improves efficiency

- Reduces operational chaos

- Increases customer satisfaction

- Saves money in the long run

Key Objectives of Lean Management

- Eliminating waste from every process: Lean focuses on eliminating activities that do not add value, including unnecessary steps, delays, rework, and excess movement to improve efficiency and reduce wasted time and resources.

- Increasing productivity without increasing workload: Lean provides ways to improve the structure of work by eliminating bottlenecks and streamlining workflow. This leads to producing higher-quality results faster with less stress and time spent.

- Delivering higher quality products and services: By emphasizing the need for quality at every stage of the process, Lean helps organizations create higher-quality products and services. Through the use of standardization, building in checks, and utilizing error-prevention methods, Lean ensures fewer product defects and more consistent output.

- Cutting down operational costs: Lean decreases waste, reduces rework, as well as optimizes material and resource use, thus enabling organizations to achieve significantly lower costs of production (i.e., Operations) and, therefore, reduces overall costs from Operations.

- Increasing customers’ satisfaction: Lean also aligns processes between the business and its customers, providing customers with faster delivery, better quality service, and more reliable results, leading to an improved experience for all customers.

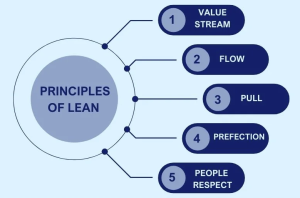

5 Core Principles of Lean Management

*engineersguidebook.com

In order to implement Lean Management effectively within the company, it is necessary to follow the 5 core principles of this method.

| Principle | What It Means | Why It Matters |

| Value | Understand what the customer is truly willing to pay for | Prevents unnecessary work and focuses on real customer needs |

| Value Stream | Map all steps involved in delivering a product or service | Helps identify waste and unnecessary steps |

| Flow | Ensure work moves smoothly without delays or bottlenecks | Reduces waiting time and improves speed |

| Pull | Produce only what is needed, when it’s needed | Prevents overproduction and excess inventory |

| Perfection | Continuously improve processes | Builds a culture of ongoing growth and innovation |

Types of Waste in Lean Management: DOWNTIME

- Defects: Defects are those products that do not meet the standard quality or specifications required by stakeholders or customers. There is a need for rework or replacements, and this leads to material waste, effort, and time. There are few common causes of defects that include poor design, improper assembly,miscommunication, material and component failure, and so on.

Thus, to avoid defects, companies implement quality control measures such as Total Quality Management and Six Sigma, and continuous improvement processes like Kaizen. - Overproduction: When a company produces more products and/or services than the consumer requires, the result is excess inventory, increased storage costs, and the potential for a product to become obsolete or not used at all. Therefore, overproduction can be considered one of the MOST damaging forms of waste because there are typically associated or compounded wastes that result from the overproduction of product/services.

- Waiting Waste: Waiting time is waste when either the employee, machine, or process is physically disallowed from doing its job due to delays and/or a lack of approval (delay caused by waiting to get approval), poor coordination between departments, or a system failure.

- Non-Utilised Talent: Non-utilised talent occurs when there is loss of employee’s knowledge, skills, and abilities. These types of underutilisation not only demotivate employees but also take the organisation valuable insights and innovation that could lead to process, products, and services improvements.

- Transportation waste: Poorly configured workstations and inefficiently designed process flows both contribute to the amount of excess transportation waste within an operation. This also leads to employees having to perform unnecessary handling of products, information, and materials, which increases the amount of time and effort associated with it.

- Inventory Waste : Excess inventory is the combination of raw materials, work-in-progress, and finished goods that are being stored or have not been sold. It represents a drain on an organisation’s capital resources, takes up valuable space in warehouses, and creates opportunities for loss, damage, and obsolescence.

- Motion Waste: Unnecessary motion is when a worker must move additional distances (for example, walking further than necessary, walking to look for tools, bending or stretching to reach for items) as a result of either poor workplace design or layout. Unnecessary motion reduces a worker’s productivity and increases the potential for fatigue.

- Excess Processing Waste: An example of overprocessing is when an organization performs excessive or unnecessary work on its business processes. Examples of this include excessive approvals and repeated inspections, as well as complex (or confusing) steps in using software to complete the business process and excessive amounts of paperwork.

Lean Tools and Techniques

5S Methodology

This is the first step in any Lean Transformation which is used to create a clean, organised and effective work environment. By sorting through the clutter of ‘stuff’, visual management, cleaning, standardizing and sustaining the practices of the five S’s, you create the foundation for an efficient and safe workplace.

Kaizen Method

The term “Kaizen,” which translates to “continuous improvement,” describes a philosophy that encourages all team members to think creatively about how to improve their work processes consistently yet steadily every day with small improvements rather than waiting for significant changes.

Instead of concentrating on creating large-scale changes at once, Kaizen focuses on creating continuous, incremental improvements in all areas of business operations, leading to substantial gains in quality, speed, and morale for employees.

Value Stream Mapping (VSM)

Value Stream Mapping (VSM) utilizes a strong visual way of representing every step in any given value stream, including raw materials, production, and shipping. Human Resources have the capability to clearly see all components of every process, helping them to identify delays, redundancies, and waste within their processes so that they can better design their workflows to operate more smoothly, quickly and economically.

Kanban System

Using the Kanban System, teams utilize visual boards or digital tools to see their work and keep track of it. They place tasks into columns defined as “To Do,” “In Progress,” and “Completed.” Using this methodology increases visibility of task status, prevents overload of tasks by one team member, and allows for a continuous flow of work without delays from unexpected interruptions.

Just-In-Time

This method is based on the concept of producing an item exactly when it is needed, and the amount needed at that time. Therefore, the JIT Model will eliminate excess inventory, lower storage expenses and reduce waste due to overproduction.

Poka-Yoke

Poka-Yoke (error-proofing) is simply a way to make sure that mistakes are prevented before they can occur. Using methods such as color coding, checklists, sensors, and design elements to guarantee that processes are more dependable and products are free from defects all contribute to the error-proofing process under Poka-Yoke.

Benefits of Lean Management

*sprintzeal.com

There are significant advantages for managers in implementing Lean Management methods:

- Waste Reduction – It is important to identify and eliminate all types of waste in processes, materials, time, and effort. By eliminating wasteful activities, businesses will incur less unnecessary costs, and their overall efficiency will be improved. This will allow them to better utilize their available resources, as well as to perform more efficiently.

- Improved Quality – Lean promotes both error prevention and standardisation, while also promoting continual improvement through Kaizen. These methods will help to minimise errors or inconsistencies in products or services, ultimately resulting in increased customer satisfaction and brand reputation in the marketplace.

- Higher Productivity – Lean maximises productivity by streamlining workflows, eliminating bottlenecks and allowing for the unencumbered flow of materials and information throughout the organization. Optimizing processes results in teams being able to produce more in less time without any increase in their existing workloads.

- Improves Employee Engagement: Employee engagement within the organization has improved as a result of Lean’s emphasis on a culture of employee involvement in identifying and solving business problems and opportunities for improvement. Employees now feel empowered to identify potential solutions to problems, own their individual responsibilities, and contribute positively to the overall growth of the organization.

Real-World Examples of Lean Management

Toyota

Toyota is considered the Leader in Lean Management with its world-renowned Toyota Production System based on a ‘Just in Time’ approach, along with emphasis on continuous improvement and respect for all individuals.

Amazon

Amazon has focused on utilising Lean Principles to enhance Warehouse Operations, minimize Wait Times and maximize Customer Delivery Efficiency.

Nike

Nike has implemented a variety of Lean Practices into their Manufacturing Processes which help to minimise Waste of Raw Materials, reduce Production Timelines, and Improve Sustainability.

Healthcare Sector

Hospitals are utilizing Lean Methodologies within their Operations, to streamline Waiting Times, effectively manage Staff Scheduling, and increase Patient Quality of Care.

Want to Be Proficient in Lean Management?

Through Jaro Education you will have access to leading online MBA programs that are focused on business and management disciplines offered by some of the most highly respected universities worldwide.

You will gain the following benefits:

- Learn modern management concepts like Lean, Six Sigma, Agile, and Operations Excellence.

- Gain practical leadership and decision-making skills.

- Access global faculty and expert-led sessions.

- Enjoy flexible learning that works around your job.

Our Online MBA Programmes:

| University / Institute | Program Type | Delivery Mode |

| Parul University | Online MBA | Online |

| MAHE (Manipal Academy of Higher Education) | Online MBA | Online |

| Symbiosis SSODL | Online MBA | Online |

| Manipal University Jaipur | Online MBA | Online |

| Chandigarh University | Online MBA | Online |

| DPU-COL (Dr. D. Y. Patil) | Online MBA | Online |

| IIM Nagpur | Blended MBA | Blended (Online + Campus) |

| IIM Mumbai | Executive MBA | Executive |

| Bharati Vidyapeeth (BVDU) | MBA | Online |

| Dayananda Sagar University (DSU) | Executive MBA | Executive |

Conclusion

Lean Management does not mean taking shortcuts, but rather eliminating waste through smart strategies. Organisations that use lean management are more productive (faster, higher quality, more customer-oriented), while those that understand how the system works build their capacity to continually improve.

The application of lean thinking can change the way students, professionals, and entrepreneurs address issues and make decisions. With the support and guidance of the appropriate education, for example, an Online MBA program offered by Jaro, you can further develop these concepts into effective leadership abilities.

Frequently Asked Questions